自動灌膠機封裝過程中液料的處理!

在自動灌裝機和點膠機生產前,應根據包裝的實際要求選擇包裝設備。液體物料的貯存、除霜、加熱、攪拌、干燥也是需要特別注意的因素。

Before the production of automatic filling machine and dispensing machine, packaging equipment should be selected according to the actual requirements of packaging. Storage, defrosting, heating, stirring and drying of liquid materials are also factors requiring special attention.

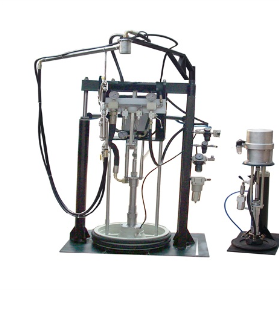

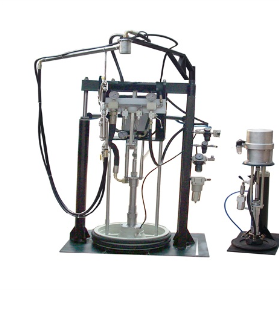

在自動灌裝機和分配器包裝前,我們通常將物料放入一個特殊的壓力桶中。在包裝設備的驅動下,液體物料將被排出。為了起見,通常將液體物料儲存在所有生銹鋼的壓力桶中。一般需要配備必要的氣壓計、攪拌系統(tǒng)、液位報警顯示系統(tǒng)等設備。為了防止液體物質的泄漏,我們必須確保壓力桶具有良好的氣密性。市場上常用的壓力桶是略小的2L、3L、5L、略大的10L、20L。

Before the automatic filler and distributor are packed, we usually put the material into a special pressure barrel. Driven by packaging equipment, liquid material will be discharged. For safety, liquid materials are usually stored in all pressure drums of rusty steel. In general, it is necessary to equip with barometer, mixing system, liquid level alarm display system and other equipment. In order to prevent the leakage of liquid substances, we must ensure that the pressure barrel has good air tightness. The commonly used pressure barrels on the market are slightly smaller 2L, 3L, 5L, slightly larger 10L, 20L.

在包裝過程中,膠水中的氣泡會對包裝質量產生嚴重的影響。因此,自動點膠機、灌裝機與常規(guī)UV膠、導電膠包裝時,必須進行凝膠除霜處理。所謂除霜過程的目的是將凝膠內的氣泡減少到接近0。外部真空泵通常用于去除氣泡。隨著真空泵設備技術的不斷改進,無油真空泵已經能夠幫助減少流體中的氣泡,解決噪聲問題。

In the packaging process, the bubbles in glue will have a serious impact on the packaging quality. Therefore, the automatic dispensing machine and the filling machine must be treated with gel defrosting when packing with conventional UV adhesive and conductive adhesive. The purpose of the so-called defrosting process is to reduce the bubbles in the gel to nearly 0. External vacuum pumps are usually used to remove bubbles. With the continuous improvement of vacuum pump equipment technology, oil-free vacuum pump has been able to help reduce bubbles in fluid and solve the problem of noise.

時間壓力:這是目前應用廣泛的技術。它是隨著SMT技術的發(fā)展而引進的個技術,并被業(yè)界廣泛接受。它也有較長的歷史比其他配藥技術。

Time Pressure: This is the most widely used technology at present. It is the first technology introduced with the development of SMT technology and widely accepted by the industry. It also has a longer history than other dispensing techniques.

其主要優(yōu)點是:結構和原理簡單,使用和維護成本低;更換桶針方便,通過更換零件可以滴下不同量的膠水;設備清洗保養(yǎng)方便;該系統(tǒng)具有靈活性,適用于不同粘度的膠液。

Its main advantages are: simple structure and principle, low cost of use and maintenance; convenient replacement of barrel needles, different amounts of glue can be dripped by changing parts; easy cleaning and maintenance of equipment; flexible system, applicable to different viscosity glue.

缺點:膠料由空氣脈沖推動,分膠周期較長。因此,在高速點膠時,速度有限,一般可達每小時40000點,隨著點膠速度的增加,很難保證點膠點的一致性:每次點膠時,物料桶內的點膠液全部被壓縮;

Disadvantage: The rubber is driven by air pulse and has a long separating period. Therefore, when dispensing at high speed, the speed is limited, generally up to 40,000 points per hour. With the increase of dispensing speed, it is difficult to ensure the consistency of dispensing point: every dispensing time, the dispensing liquid in the material barrel is compressed;

料筒膠量的不同使其對空氣脈沖的反應不同,膠點不一致;如0805或0603包裝的膠點很難滴出,如果包裝達到0402或更少,則該技術無法做任何事情。

The different amount of glue in the barrel makes its reaction to air pulse different and the glue points are different. If the glue points of 0805 or 0603 packaging are difficult to drip out, if the packaging reaches 0402 or less, the technology can not do anything.

上一篇:自動點膠機用發(fā)泡膠怎么清洗?

下一篇:自動打膠機膠體粘度對產品性能的影響!