雙組份打膠機的結構原理以及打膠操作

打膠機的結構原理

Structural principle of glue applicator

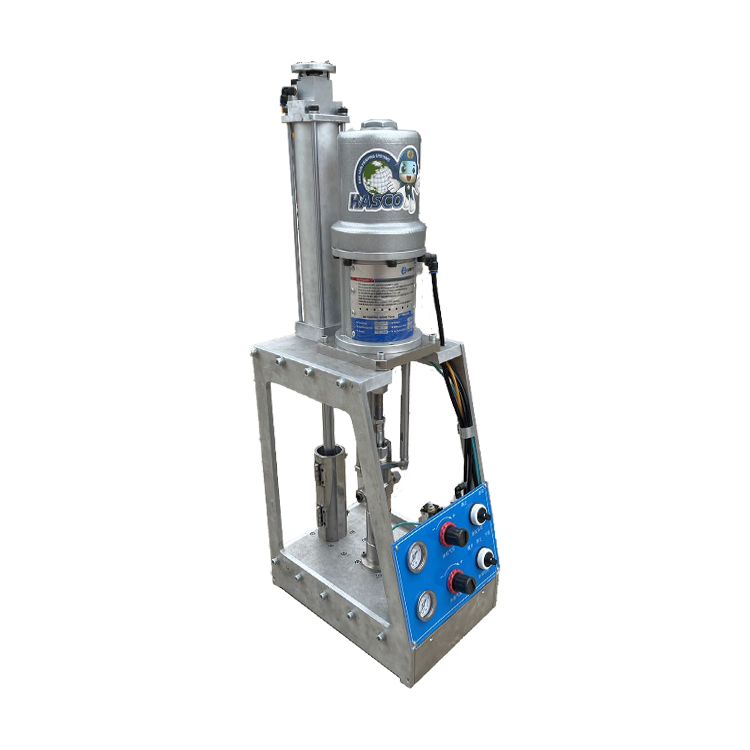

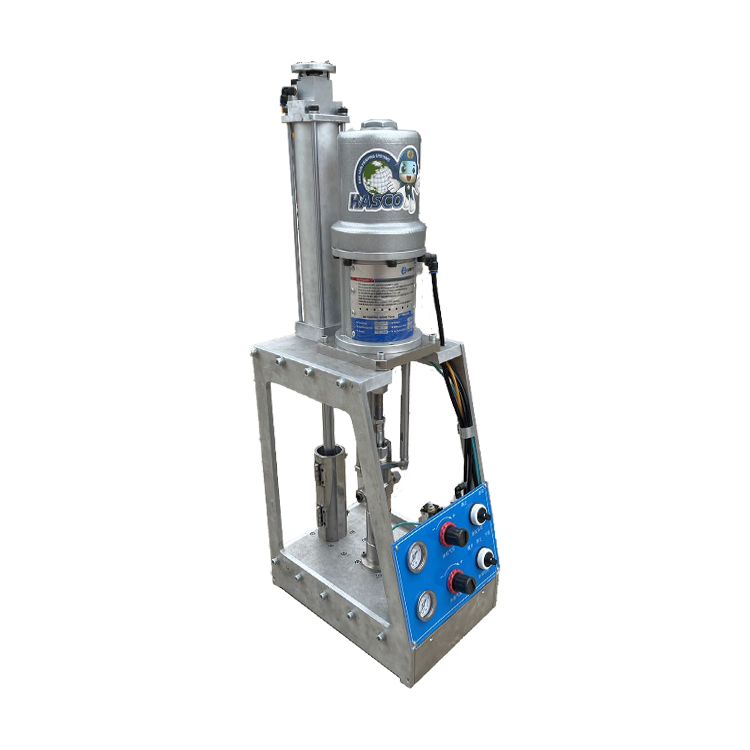

雙組份涂膠機由A、B膠泵、氣動系統、升降機構、機架等組成。現分別介紹如下:

The two-component glue applicator is composed of a and B glue pumps, pneumatic system, lifting mechanism, frame, etc. Here are the following:

1.膠泵:

1. Rubber pump:

(1)A、B組份各設一個膠泵,在各自的氣馬達驅動下,分別作往復運動,將膠吸入并壓出。A、B膠泵分別與壓膠盤固定在一起,再與機架連接組成各自的系統。

(1) Components a and B are respectively equipped with a glue pump, which is driven by their respective air motors to make reciprocating motion to suck in and press out the glue. A. B glue pump is respectively fixed with glue pressing plate, and then connected with the frame to form their own system.

(2)A、B組份的配比是通過比例杠桿進行調節:向里調節,B出膠量減少,向外調節,B出膠量增加。通過調節比例杠桿來控制B膠的出膠量,從而控制A、B膠的配比。

(2) The proportion of components a and B is adjusted through the proportional lever: adjust inward, the glue output of B decreases, adjust outward, and the glue output of B increases. Adjust the proportional lever to control the glue output of B glue, so as to control the ratio of a and B glue.

(3)出膠量:由氣源處理器控制,逆時針調節,出膠量增加,順時針調節出膠量減小。(這里指總出膠量) 本膠泵通過比例杠桿調節A、B膠量配比,具有操作靈活,性能穩定,調節范圍大等特點。

(3) Glue output: controlled by the air source processor, adjust counterclockwise, the glue output increases, and adjust clockwise, the glue output decreases. (here refers to the total glue output) this glue pump adjusts the proportion of a and B glue through the proportional lever, which has the characteristics of flexible operation, stable performance, large adjustment range and so on.

2.升降機構:

2. Lifting mechanism:

A、B組份膠泵分別設一套氣動升降機構,該升降機構分別由兩個氣缸并聯組成,并通過橫梁固定連接各自的泵體。其目的之一是將兩缸的作用力通過壓盤作用在膠面上,壓力大小由調壓閥調節,一般調整在0.3MPa左右;其二,當需要更換膠桶時,氣缸可將壓盤提起。離開膠桶,以便更變新的膠桶。

A. The rubber pump of group B is equipped with a set of pneumatic lifting mechanism, which is composed of two cylinders in parallel, and is fixedly connected to their respective pump bodies through beams. One of its purposes is to act the force of the two cylinders on the rubber surface through the pressure plate. The pressure is adjusted by the pressure regulating valve, which is generally adjusted at about 0.3MPa; Second, when the rubber barrel needs to be replaced, the cylinder can lift the pressure plate. Leave the plastic bucket so that it can be renewed.

打膠機打膠操作:

Gluing operation of gluing machine:

1)松開比例杠桿上的比例泵鎖緊螺釘,將比例泵內外調整所需比例。只有當A膠和B膠的配比達到正常值時,才可進行下面的操作。

1) Loosen the locking screw of the proportional pump on the proportional lever and adjust the inside and outside of the proportional pump to the required proportion. The following operations can be carried out only when the ratio of glue a and glue B reaches the normal value.

2)置選擇旋鈕于

雙組份打膠機的A、B泵開,將膠槍出口對準兩片玻璃的中縫,打開膠槍開關,以適當速度平穩地移動膠槍使玻璃槽內的雙組份膠填滿充實為佳。打膠結束時關閉膠槍。

2) Place the selection knob on the A and B pumps of the two-component glue dispenser, align the glue gun outlet with the middle seam of the two pieces of glass, turn on the glue gun switch, and move the glue gun smoothly at an appropriate speed to fill the two-component glue in the glass tank. Close the glue gun at the end of gluing.

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.e846lbsv.cn And consult our staff, will serve you wholeheartedly.

上一篇:怎么區分汽車車燈大燈是熱膠還是冷膠?

下一篇:關于打膠機有幾個常出現的問題要了解